Currently, there are no competitive products that attempt to increase combustion efficiency and thus burn up particulates in the combustion chamber. ALL competitive efforts to reduce particulate matter emissions is currently done in the exhaust. That is for both new engines and retro-fit devices. However, because there is still a large amount of particulates entering into the Diesel Particulate Filter (DPF), management of these systems are still very problematic, particularly in commercial applications where often the engines and vehicles are rendered inoperable when the DPF gets clogged with particulates.

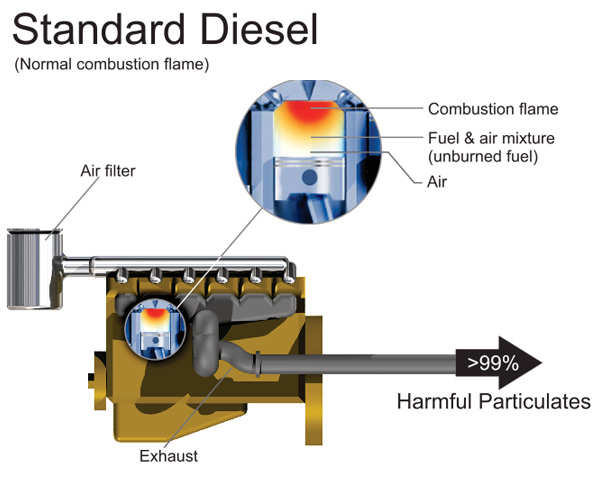

The following illustration shows the normal combustion of diesel fuel and the large amount of unburned fuel that exits the exhaust. During combustion, all of the fuel that enters the combustion chamber is not burned. This is standard for all diesel engines. To make matters worst, the amount of unburned fuel is even greater when the engine is at idle.

As can be seen in the illustration, there is a large amount of particulates created with normal diesel combustion.

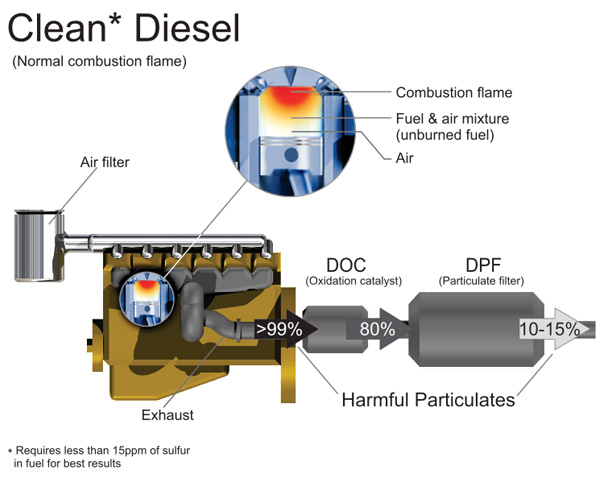

The following illustration is of a "Clean Diesel" engine. As can be seen, the combustion is identical to the standard diesel engines. However, efforts are made to remove the harmful gases and particulates from the exhaust. It should also be noted that "Clean Diesel" requires low sulfur diesel fuel. Otherwise, the emissions are even more harmful with high sulfur diesel fuel.

As can also be seen in this illustration, there is a large amount of particulates created with the clean diesel combustion. However, the Diesel Oxidation Catalyst and the Diesel Particulate filter is responsible for removing the particulates. As mentioned above because there is still a large amount of particulates entering into the Diesel Particulate Filter (DPF), management of these systems are still very problematic, particularly in commercial applications where often the engines and vehicles are rendered inoperable when the DPF gets clogged with particulates. Many times, there is no forewarning of the DPF failure.

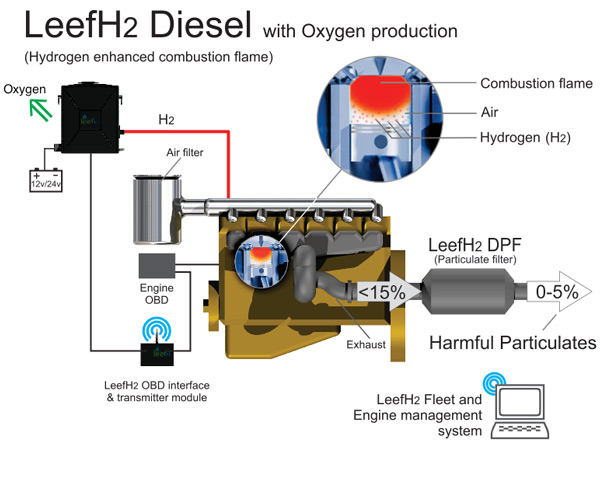

The following is an illustration of the Leefh2 Diesel System. The combustion flame is greatly enhanced with the addition of the Hydrogen gas, thus making the amount of unburned fuel exiting the combustion chamber and entering the exhaust significantly less than with normal diesel combustion. During this process breathable oxygen is also released to the atmosphere.

As can be seen from the illustration, the amount of particulates are dramatically reduced because of a more complete combustion in the combustion chamber of the diesel engine. The Leefh2 technology can be used with both old and new diesel engines with the same result.

The Leefh2 technology system includes an engine OBD (on-board diagnostic) interface with wireless transmission capabilities. Leefh2 operational status, engine data and other pertinent vehicle or engine data is wirelessly transmitted to a Fleet Management system so information on engines and vehicles is readily available.

In addition to the increased combustion efficiency and less harmful particulates, breathable oxygen is released to the atmosphere as a positive environmental by-product.